The construction of a cold storage warehouse seems so easy at first an enclosure and some heavy refrigeration equipment. But the fact is much more layered, and that’s where cold storage construction costs sneak into the conversation. Each decision from the insulation panels to the floor has a silent influence over the total. Others underestimate how even small upgrades or design tweaks can push numbers up, which is why knowing from where those costs come makes the process much less mysterious and a lot less stressful. Again, an equal understanding of how Cold Storage Construction Services work is also good because good services can rather practically be efficient without unnecessary expenses as well delivered to the client.

Understanding Material Costs

Materials are the main driver of Cold Storage Construction Costs, as super insulation, special tight sealing doors, materials for the floors among others all sum up very quickly. There can be no cutting of corners by builders in this as temperature stability is non-negotiable. The insulation recommendation from most Cold Storage Construction Services is polystyrene or polyurethane panels, for quite impressive insulation capacity. The price of these products will vary according to their thickness and supplier. However, even small differences in the quality of their insulating qualities add up eventually to the energy bills, turning the cost of materials from a mere front-end cost to a direct impact on long-term savings. A seasoned construction team leads clients through comparisons of material deals and expensive often turns out to be the cheap bargain over time.

Choosing Equipment and Technology

The core of Cold Storage Construction Costs mainly deals with the refrigeration method. Compressors, condensers, evaporators, and control systems play a major role in defining the energy productivity of the warehouse. It’s not that Cold Storage Construction Services only provide the hardware. They even plan for the system capacity, failure redundancy, and smart monitoring solutions. For instance, a warehouse with -$30°C frozen seafood is different from a warehouse with 2°C fresh produce to operate. Such technological variances are important and they can create big swings in cost. Advanced temperature and humidity control solutions cost more at the beginning but it could massively reduce waste and enhance a longer shelf life. Good construction services usually balance client budgets with the long-term operational needs, making technology investments make sense.

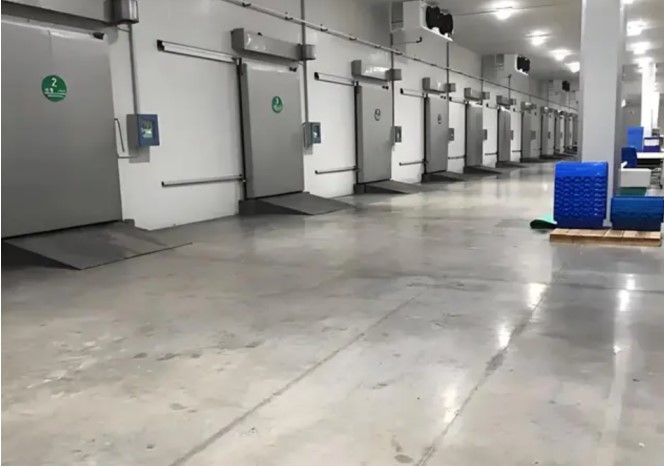

Preparing the Site and Building Stuff

Cold storage construction costs do not start from refrigeration units; they start from the time site preparation kicks off. It is inevitable clearing land, leveling surfaces, creating a strong foundation. This related cold storage construction service always gives importance to soil stability tests and proper drainage planning because even slight problems in these matters can hamper the whole structure. The very high expenses may be realized due to the use of quality materials in the construction of reinforced concrete floors. Otherwise, they will be problems to be tackled years later Industrial constructions involve the use of structural steel for frame, roofing systems designed in moisture resistance and aspects of fire safety, etc., all under the construction budget. Each of these aspects is common in general warehouse projects, yet the complexity and cost related to them are elevated by the special requirements of temperature-sensitive storage.

Labor, Know-How, and Handling Projects

Another considerable portion of Cold Storage Construction Costs is human expertise. It is very costly to get specialized labor as cold storage construction is a practice that goes beyond ordinary building practices. One may feel otherwise until they have had to hire personnel, particularly plumbers or workers capable of erecting the insulation panels, among other roles, for any cold storage facility; a slight mistake in any system can result in complete failure. Project management services handed by Cold Storage Construction Services are manned with project managers who relate well with the architect, suppliers, and group of workers in line. It would not be possible to prevent all these mistakes even if reworks are allowed. Thus, the best construction services can transparently show the labor cost, hence breaking down hourly rates and any fees paid to subcontractors and how much money goes into supervision.

Compliance and Safety Considerations

Every cold storage facility has to comply with very stringent rules, and each compliance adds its own little bit to Cold Storage Construction Costs. All elements must adhere to the food safety standards, the fire codes, and the energy codes from the thickness of the walls to the glazing at emergency exits. Generally, Cold Storage Construction Services do have a specialized sort of a professional who stays updated over these codes that will go a long way to make sure that the warehouse passes inspections without much huddle. The skipping of compliance or attempts to wriggle out of it only would lead to delays and penalties, and retrofits cost much more than doing it right the first time. For business houses handling pharmaceuticals, vaccines, or export goods, it is again their international compliance requirements that add to their budget; however, reputable services ensure that the facility is future-proofed against regulatory changes.

Things to Keep in Mind for Continued Maintenance

It would be naive to assume that once a cold store has been built, then Cold Storage Construction Costs have since stopped; there is a need for factoring in maintenance cost. Refrigeration units have to be kept under regular servicing, insulation materials require periodic inspections, plus doors should maintain seals. Usually, Cold Storage Construction Services offer such maintenance packages, or they recommend partners to offer aftercare. This will prevent unexpected breakdowns and inefficiency losses later on after the completion of the facility. Yet, strictly speaking, these are not ‘construction’ costs but are the cost of the quality of construction. A warehouse constructed with inferior materials in a slipshod manner is going to bear a higher maintenance lifetime cost; and thus construction decisions come to reverberate long after the ribbon cutting ceremony has been completed.

Place and Service Links

The location of where a warehouse is built has a huge influence on Cold Storage Construction Costs. Remote sites may require extravagant utility connections for power and water to the site; it might be in an urban area, which may involve high land and permit fees. Logistical challenges are usually factored by Cold Storage Construction Services during planning. For example, a location that does not have a very good power supply will need installations of backup generators or solar integrations, which are initial expenses but are very viable. It should also have easy accessibility for trucks and shipping partners. A warehouse at a primary logistics hub may have high land costs but low long-term transport expenses; hence, it is a trade-off that construction experts will help in analyzing.

Finding a Balance Between Cost and Quality

In the end, it can be said that Cold Storage Construction Costs are a balance between fixed solutions and variable decisions. Clients demand robustness, productivity, and compliance but they also want affordability. It is here that Cold Storage Construction Services become not just construction workers but partners. A reliable service provider is one who takes its customers through areas possible to cut down cost without taking any risks like advising for an average refrigerating unit with much investment in the insulation. They show where cutting costs would simply be stupid, like completely skipping over secondary power backup systems or really poor quality flooring. Getting it right balances such that the warehouse does not only get within the budget but gives out sustainable operations for years to come.

Human-like: Long-Term Worth and Return on Investment

What makes Cold Storage Construction Costs worth the investment is the potential for long-term value; increased operation and energy-efficient systems, and lower cumulative operational bills which minimize the maintenance and compliance-related interruptions in business or operations. Cold Storage Construction Services always tout ROI as well, helping costumers look past the initial sticker price at the front end. An ideal cold storage warehouse stores more than just products; it stores a supply chain, security for sensitive goods, and trust for customers. Every single dollar invested in careful construction and reliable services is part of a whole wherein efficiency, safety, and profit all may be found.